To access the Mastercam Basics Series, visit and log in with your Mastercam account credentials. You will then set up stock, create toolpaths, and generate G-code.Įverything in the Mastercam Basics Series is available free of charge on Mastercam University, an online platform for learning Mastercam, to anyone interested in learning about the foundations of manufacturing and the world’s leading CAD/CAM software. In this course, you will use Mastercam to create and program a simple part beginning with creating 2D wireframe geometry to create a solid.

This course is a brief introduction to what Mastercam does, what it is used for, and why it is used around the world. Have you ever wondered how something was made? This course will introduce you to some basic manufacturing concepts and methods, take a closer look at different types of machining, and explore how CAD/CAM software interfaces with machines. Three courses are available, with eight videos and fifty minutes of content. The series stemmed from a partnership between Mastercam’s Training and Education departments to provide introductory content about manufacturing concepts, methods, and practices. The Mastercam Basics Series is designed for educators and students.

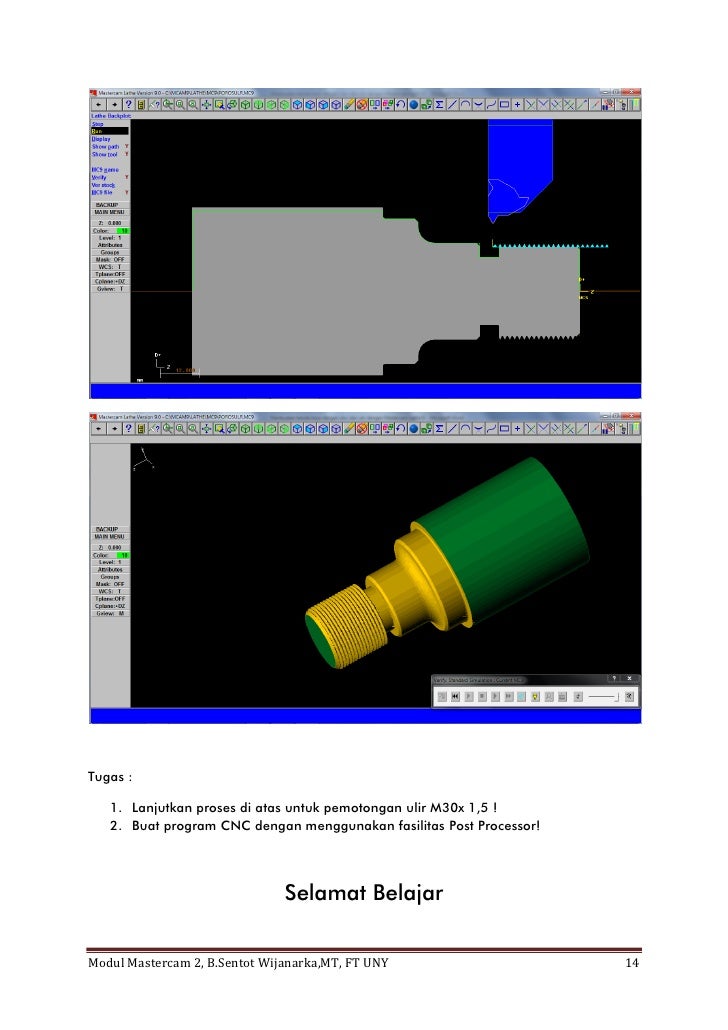

Quickly translate geometry and create a part transfer operation from the main spindle to sub spindle and/or a bar pull operation prior to a cutoff toolpath. Tool Inspection lets you automatically stop machining, allowing you to check the insert during your roughing, finishing, and grooving operations. Intelligent ID and OD roughing, including roughing to a boundary for castings. Variable Depth Roughing prevents "notching" which results when a roughing pass repeatedly engages the material at the same point. New plunge turn toolpath designed specifically for ISCAR cut grip inserts. Dependable toolpath verification gives you the confidence to run the most complex toolpaths on your machine, and Machine and Control Definition delivers a new way to make sure your parts are done right the first time.Įasy roughing, finishing, threading, grooving, boring, drilling, and cut off.įull mill/turn capabilities when combined with Mastercam Mill. Mastercam Lathe delivers a set of C-axis programming tools, with greatly expanded options when combined with Mastercam Mill, such as face contour and drilling, and cross contour and drilling. From the streamlined CAD engine and solid model machining, to powerful roughing and finishing, Mastercam Lathe gives you a variety of techniques to turn all of your parts exactly as you need them. Mastercam Lathe gives you a set of tools that impact your entire process. Efficient turning means more than just programming a toolpath.

0 kommentar(er)

0 kommentar(er)